You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The view or two from my "office"

- Thread starter JessicaTam

- Start date

- Featured

chelzmalee

Member

- Joined

- Mar 23, 2015

- Posts

- 362

- Qantas

- Bronze

RB

Established Member

- Joined

- Nov 17, 2004

- Posts

- 4,308

Going out there before we leave this morning. Saw a few rally cars arriving yesterday. There was also a group of long distance bike riders on a charity ride the other day. Plenty of visitors in town but very dry around here@RB, I was meant to be in Burra today for the AGL Rally of the Heartland, had to change my plans. Will you go out to the farm house featured on the Midnight Oil album?

Captain Halliday

Established Member

- Joined

- Jun 1, 2014

- Posts

- 4,904

chelzmalee

Member

- Joined

- Mar 23, 2015

- Posts

- 362

- Qantas

- Bronze

Australia's highest-earning Velocity Frequent Flyer credit card: Offer expires: 30 Apr 2025

- Earn 100,000 bonus Velocity Points

- Get unlimited Virgin Australia Lounge access

- Enjoy a complimentary return Virgin Australia domestic flight each year

- Earn 100,000 bonus Velocity Points

- Get unlimited Virgin Australia Lounge access

- Enjoy a complimentary return Virgin Australia domestic flight each year

AFF Supporters can remove this and all advertisements

OATEK

Senior Member

- Joined

- Apr 12, 2013

- Posts

- 5,682

VPS

Senior Member

- Joined

- Apr 2, 2011

- Posts

- 9,307

- Qantas

- LT Gold

- Virgin

- Gold

It is probably too late but Terroir is an excellent restaurant in AuburnA day spent around Auburn Sth Aust

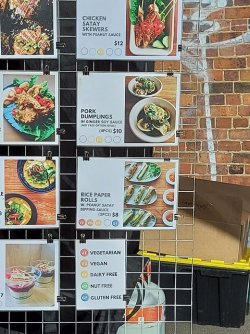

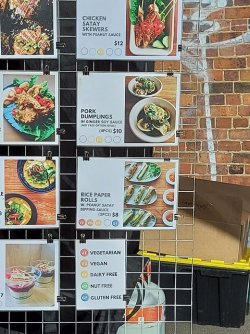

View attachment 247408

View attachment 247409

View attachment 247410

drron

Veteran Member

- Joined

- Jul 4, 2002

- Posts

- 36,298

This morning's office.Harvest Market,Launceston.Breakfast.

.

.

.

.

Next saturday's breakfast will come from here.

.

.

Late morning office.The Tramway Museum.Free except if you want a tram ride-$5 or $4.50 for a senior.

.

.

My personal tram arrives.Even had my number .

.

.

And has to take it's own power with it.

.

.

.

. .

.Next saturday's breakfast will come from here.

.

.Late morning office.The Tramway Museum.Free except if you want a tram ride-$5 or $4.50 for a senior.

.

.My personal tram arrives.Even had my number .

.

.And has to take it's own power with it.

.

.- Joined

- Jun 20, 2002

- Posts

- 17,748

- Qantas

- Gold

- Virgin

- Platinum

- Joined

- Jun 7, 2006

- Posts

- 11,515

- Qantas

- LT Gold

I got dusted off on a beautiful day yesterday to help with seeding some canola trials near Beverley, about 1.5h drive SE of PER.

Common agricultural trials are for things like cultivar (aka variety) comparison and evaluation. Generally, plots are 1.2 m (6 rows) wide x 10 m long. They need to be sown accurately in a grid with a precision seeder. A typical trial might be 12 varieties x 4 replications , so 48 plots, in a RCB (randomised complete block) statistical design with an ANOVA (analysis of variance) conducted on yield, or other parameters, at the end to separate effects.

Working in an area 40 m wide x about 100 m long, we sowed about four trials, running back and forth across the width of the site (ie. 4 plots sown in each run). Prior to sowing, the area was sprayed with herbicide with the rig on the ute.

Needing cm precision, we set up a differential GPS station locked to about 19 satellites. That in turn controlled the location of the tractor, which has fully automatic steering capability. So, once I swung the machine around and generally lined it up for another 40 m run, all I had to do was hit the auto-steer icon on the screen, switch on the precision cone-seeder seed feeding mechanism and lower the hydraulically-controlled tynes and press-wheels prior to the edge, then not touch the steering wheel until the run was completed and it was time to turn off auto-steer and the seed feeder and raise the tynes before steering manually for the next run.

The other operator was on the seeder, feeding the envelopes of coded seeds into the canister above the inverted cone (designed to spread the seeds very evenly) successively one at a time, with the gate opening precisely under automatic GPS control.

This is the same minimum-tillage methodology almost universally used in broadacre cropping. The tynes cut a narrow furrow into which the measured seed and fertiliser drops, while the rubber-edged press wheels apply pressure to ensure good soil/seed contact.

Common agricultural trials are for things like cultivar (aka variety) comparison and evaluation. Generally, plots are 1.2 m (6 rows) wide x 10 m long. They need to be sown accurately in a grid with a precision seeder. A typical trial might be 12 varieties x 4 replications , so 48 plots, in a RCB (randomised complete block) statistical design with an ANOVA (analysis of variance) conducted on yield, or other parameters, at the end to separate effects.

Working in an area 40 m wide x about 100 m long, we sowed about four trials, running back and forth across the width of the site (ie. 4 plots sown in each run). Prior to sowing, the area was sprayed with herbicide with the rig on the ute.

Needing cm precision, we set up a differential GPS station locked to about 19 satellites. That in turn controlled the location of the tractor, which has fully automatic steering capability. So, once I swung the machine around and generally lined it up for another 40 m run, all I had to do was hit the auto-steer icon on the screen, switch on the precision cone-seeder seed feeding mechanism and lower the hydraulically-controlled tynes and press-wheels prior to the edge, then not touch the steering wheel until the run was completed and it was time to turn off auto-steer and the seed feeder and raise the tynes before steering manually for the next run.

The other operator was on the seeder, feeding the envelopes of coded seeds into the canister above the inverted cone (designed to spread the seeds very evenly) successively one at a time, with the gate opening precisely under automatic GPS control.

This is the same minimum-tillage methodology almost universally used in broadacre cropping. The tynes cut a narrow furrow into which the measured seed and fertiliser drops, while the rubber-edged press wheels apply pressure to ensure good soil/seed contact.

Become an AFF member!

Join Australian Frequent Flyer (AFF) for free and unlock insider tips, exclusive deals, and global meetups with 65,000+ frequent flyers.AFF members can also access our Frequent Flyer Training courses, and upgrade to Fast-track your way to expert traveller status and unlock even more exclusive discounts!

AFF forum abbreviations

Wondering about Y, J or any of the other abbreviations used on our forum?Check out our guide to common AFF acronyms & abbreviations.

Currently Active Users

- z28

- mviy

- Foz

- Ryan Bingham

- FlyingFiona

- stevenaus

- cgichard

- Mattg

- gxia

- PerPH

- tim84

- ADLhighflyer

- drron

- Kateag2

- nancypants

- jkbaus

- Austman

- moa999

- BobH

- bits

- adenda

- lunne

- lazblue

- Black Duck

- diamondhands

- Buzzard

- Berlin

- Big John

- scotty_mel

- Denali

- Quickstatus

- Steady

- smiliemonster

- Economy_Gold

- PERLHR

- cjd600

- love_the_life

- Himeno

- gaz0303

- m535607

- aspro2

- Flyfrequently

- Junior royal

- Flyinfish

- Grrr

- joelby

- simmomelb

- Kristian

- aus_flyer

- Saab34

Total: 1,862 (members: 78, guests: 1,784)